How to Print Perfect Models from STL Files

- eastcoast3dz

- Nov 24, 2025

- 4 min read

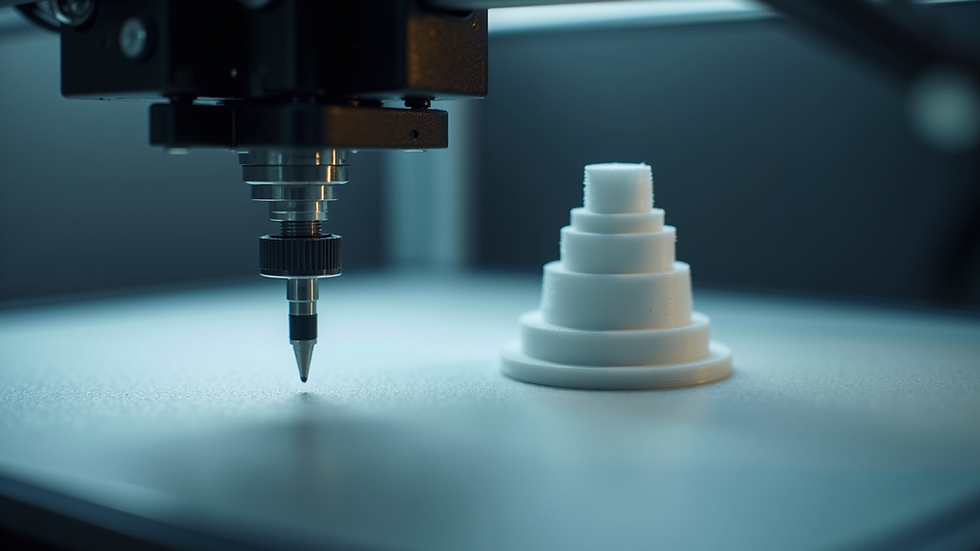

Printing 3D STL files can be a rewarding experience when you see your digital designs come to life as physical objects. However, achieving perfect prints requires more than just loading a file and hitting print. It involves understanding the nuances of the STL format, preparing your model correctly, and optimizing your 3D printer settings. This guide will walk you through the essential steps to ensure your 3D prints are flawless and meet your expectations.

Understanding the Basics of Printing 3D STL Files

Before diving into the printing process, it’s important to understand what an STL file is and why it’s the standard for 3D printing. STL stands for "stereolithography" and represents the surface geometry of a 3D object without any color, texture, or other attributes. It describes the shape using a mesh of triangles.

When preparing to print, the quality of your STL file directly impacts the final output. Here are some key points to consider:

File Resolution: Higher resolution STL files have more triangles, which means smoother surfaces but larger file sizes.

File Integrity: The STL must be "watertight" with no holes or non-manifold edges to avoid printing errors.

Model Orientation: How the model is positioned on the print bed affects print quality and support requirements.

Taking time to inspect and repair your STL file using software like Meshmixer or Netfabb can save you from failed prints and wasted material.

Essential Tips for Printing 3D STL Files Successfully

Once your STL file is ready, the next step is to optimize your 3D printer settings and environment. Here are practical tips to help you print perfect models:

Choose the Right Material

Different materials have unique properties. PLA is beginner-friendly and prints easily, while ABS offers more durability but requires a heated bed and enclosure.

Calibrate Your Printer

Regular calibration of the bed level, nozzle height, and extrusion rate ensures consistent print quality.

Adjust Layer Height and Speed

Lower layer heights (0.1-0.2 mm) produce finer details but increase print time. Slower print speeds reduce defects like stringing and layer misalignment.

Use Supports Wisely

Overhangs beyond 45 degrees usually need supports. Use slicer software to generate supports only where necessary to minimize cleanup.

Optimize Infill Settings

Infill density affects strength and weight. For decorative models, 10-20% infill is sufficient, while functional parts may require 50% or more.

Control Cooling

Proper cooling prevents warping and improves surface finish. Use part cooling fans especially when printing PLA.

Monitor First Layers

The first few layers are critical for adhesion. Ensure the bed is clean and consider using adhesives like glue stick or painter’s tape.

By following these tips, you can significantly improve the success rate of your prints and reduce post-processing time.

Preparing STL Files for Printing: Software and Techniques

Preparing your STL file involves more than just slicing. Here’s how to get your model print-ready:

Check for Errors: Use tools like Microsoft 3D Builder or Netfabb to detect and fix holes, flipped normals, or intersecting faces.

Scale and Position: Ensure your model fits within your printer’s build volume. Position it to minimize supports and optimize strength.

Hollowing Models: For large prints, hollowing reduces material use and print time. Add drainage holes to avoid trapped resin or filament.

Slicing Software: Programs like Cura, PrusaSlicer, or Simplify3D convert your STL into G-code instructions. Customize settings like layer height, infill, and supports here.

Remember, each model may require different settings depending on its complexity and intended use.

Troubleshooting Common Issues in STL File Printing

Even with careful preparation, issues can arise during printing. Here are common problems and how to fix them:

Warping: Edges lifting from the bed. Fix by using a heated bed, adding brim or raft, and improving bed adhesion.

Stringing: Thin strands of filament between parts. Reduce print temperature and increase retraction settings.

Layer Shifting: Misaligned layers due to loose belts or mechanical issues. Tighten belts and check stepper motors.

Under-Extrusion: Gaps or missing filament. Clean the nozzle, check filament quality, and calibrate extrusion multiplier.

Poor Surface Finish: Caused by incorrect print speed or cooling. Slow down printing and ensure fans are working properly.

If you encounter persistent problems, revisiting your STL file for errors or adjusting print orientation can also help.

Enhancing Your Prints Beyond the Basics

Once you master the fundamentals, you can explore advanced techniques to elevate your prints:

Multi-Material Printing: Use printers with dual extruders to combine colors or materials.

Post-Processing: Sanding, painting, or acetone vapor smoothing can improve aesthetics.

Custom Supports: Design your own supports in CAD software for easier removal.

Print Monitoring: Use webcams or smart sensors to watch prints remotely and catch failures early.

For those interested in professional-grade results, investing time in learning these techniques will pay off.

For more detailed insights and expert advice on stl file printing, explore specialized blogs and tutorials.

Taking Your 3D Printing Skills to the Next Level

Mastering printing 3D STL files is a journey of continuous learning and experimentation. By understanding your files, optimizing printer settings, and troubleshooting effectively, you can produce high-quality models consistently. Keep exploring new materials, software updates, and community tips to stay ahead in the world of 3D printing.

Happy printing!

Comments