Unlock Professional 3D Printing Services for Your Business

- eastcoast3dz

- Sep 28, 2025

- 5 min read

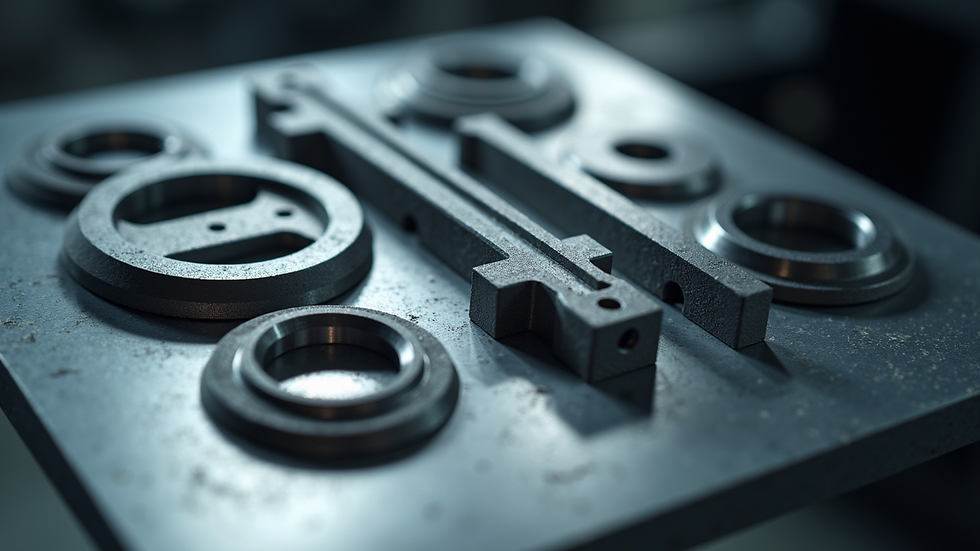

In today’s fast-paced manufacturing and design world, industrial 3D printing solutions have become a game-changer. They offer businesses the ability to create complex parts, prototypes, and products quickly and cost-effectively. Whether you are in automotive, aerospace, healthcare, or consumer goods, leveraging advanced 3D printing technology can significantly enhance your production capabilities and innovation potential.

Industrial 3D printing is not just about making objects layer by layer; it’s about transforming how products are designed, tested, and manufactured. This technology allows for customization, rapid iteration, and reduced waste, which are critical factors in staying competitive. If you want to unlock the full potential of 3D printing for your business, understanding the available services and how to integrate them is essential.

What Are Industrial 3D Printing Solutions?

Industrial 3D printing solutions refer to the use of advanced additive manufacturing technologies tailored for large-scale, high-precision, and durable production needs. Unlike consumer-grade 3D printers, industrial machines can work with a wide range of materials such as metals, high-performance plastics, and composites. These solutions are designed to meet the rigorous demands of industries requiring parts that can withstand mechanical stress, heat, and other challenging conditions.

Some key features of industrial 3D printing solutions include:

High precision and accuracy: Producing parts with tight tolerances.

Material versatility: Using metals like titanium, aluminum, and stainless steel, as well as engineering-grade polymers.

Scalability: From prototyping to small-batch production and even mass manufacturing.

Speed: Faster turnaround times compared to traditional manufacturing methods.

Customization: Ability to create complex geometries and tailor parts to specific needs.

For example, aerospace companies use industrial 3D printing to manufacture lightweight components that reduce fuel consumption. Medical device manufacturers create patient-specific implants and surgical tools with unmatched precision. These solutions enable businesses to innovate faster and reduce costs associated with tooling and inventory.

Benefits of Industrial 3D Printing Solutions for Your Business

Adopting industrial 3D printing solutions can bring numerous advantages to your business operations. Here are some of the most impactful benefits:

1. Faster Product Development Cycles

Traditional manufacturing often requires creating molds or tooling, which can take weeks or months. Industrial 3D printing eliminates this step by directly producing prototypes and functional parts. This accelerates the design iteration process, allowing your team to test and refine products rapidly.

2. Cost Efficiency

While the initial investment in industrial 3D printing might seem high, the overall cost savings are significant. You reduce material waste, lower labor costs, and avoid expensive tooling. Additionally, producing parts on-demand means you don’t have to maintain large inventories, freeing up capital.

3. Design Freedom

Industrial 3D printing allows for complex geometries that are impossible or very costly to achieve with traditional methods. This opens up new possibilities for lightweight structures, internal channels, and integrated assemblies, enhancing product performance.

4. Customization and Personalization

Businesses can offer customized products tailored to individual customer needs without increasing production costs. This is especially valuable in healthcare, fashion, and consumer goods sectors.

5. Sustainability

Additive manufacturing uses only the material needed to build the part, reducing waste significantly. Many industrial 3D printing materials are recyclable, contributing to a more sustainable production process.

By integrating these solutions, your business can stay ahead of competitors and respond quickly to market demands.

Where Can I 3D Print an Item?

If you are wondering where to get your items 3D printed, there are several options depending on your needs, budget, and project complexity.

Local 3D Printing Service Providers

Many cities have specialized 3D printing service bureaus that offer industrial-grade printing. These providers can handle everything from design consultation to final production. Working with a local service allows for easier communication, faster turnaround, and the ability to inspect prototypes in person.

Online 3D Printing Platforms

There are numerous online platforms where you can upload your 3D model, select materials, and receive the finished product by mail. These platforms often provide instant quotes and support multiple printing technologies. However, they may not offer the same level of customization or quality control as dedicated industrial providers.

In-House 3D Printing

For businesses with frequent or large-scale 3D printing needs, investing in an industrial 3D printer might be worthwhile. This option provides full control over the production process but requires expertise and maintenance.

Partnering with Professional 3D Printing Services

Outsourcing to professional 3d printing services is often the best balance between quality, cost, and convenience. These companies specialize in industrial 3D printing solutions and can guide you through material selection, design optimization, and post-processing.

Choosing the right option depends on your project timeline, complexity, and budget. For critical or high-volume parts, professional services are recommended to ensure reliability and performance.

How to Choose the Right Industrial 3D Printing Service for Your Business

Selecting the right partner for industrial 3D printing is crucial to achieving your business goals. Here are some factors to consider:

1. Expertise and Experience

Look for providers with a proven track record in your industry. They should understand the specific requirements of your application, such as material properties, certifications, and regulatory compliance.

2. Technology and Equipment

Ensure the service provider uses the latest industrial 3D printing technologies suitable for your needs. Common methods include:

Selective Laser Sintering (SLS)

Direct Metal Laser Sintering (DMLS)

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

Each technology has its strengths and limitations, so choose one that aligns with your product specifications.

3. Material Options

Verify the range of materials available, including metals, plastics, and composites. The provider should offer materials that meet your mechanical, thermal, and chemical requirements.

4. Quality Assurance

Quality control processes such as dimensional inspection, mechanical testing, and certification are essential. Ask about their quality standards and whether they provide documentation.

5. Turnaround Time and Capacity

Understand their production capacity and lead times. A reliable service should meet your deadlines without compromising quality.

6. Customer Support

Good communication and technical support can make a big difference. Choose a partner who offers design assistance, troubleshooting, and post-processing services.

By carefully evaluating these factors, you can find a 3D printing service that adds value to your business and supports your innovation journey.

Maximizing the Impact of Industrial 3D Printing Solutions

To get the most out of industrial 3D printing, consider these actionable recommendations:

Invest in Design for Additive Manufacturing (DfAM): Train your design team to optimize parts for 3D printing. This includes reducing support structures, minimizing material use, and enhancing functionality.

Prototype Early and Often: Use 3D printing to create prototypes at every stage of development. This helps identify design flaws and improve product performance.

Integrate with Traditional Manufacturing: Combine 3D printed parts with conventional components to balance cost and performance.

Leverage Post-Processing Techniques: Finishing processes like polishing, painting, or heat treatment can improve aesthetics and durability.

Monitor and Analyze Production Data: Use data from 3D printing processes to optimize parameters and improve consistency.

By adopting these strategies, your business can fully harness the advantages of industrial 3D printing solutions and drive innovation.

Industrial 3D printing solutions are revolutionizing how businesses design and manufacture products. By partnering with expert providers and embracing this technology, you can accelerate development, reduce costs, and create products that stand out in the market. Whether you need rapid prototyping or end-use parts, professional 3D printing services offer the flexibility and quality your business demands. Start exploring these solutions today to unlock new opportunities for growth and success.

Comments